At the beginning of the new year, Nano welcomed guests from afar—a delegation from a well-known Japanese machine tool enterprise arrived for inspection. Mr. Zhou Wei, the Chairman of Nano, personally led the team to greet them, and both sides engaged in in-depth discussions on product process innovation, quality control, and future deepened cooperation.

In-depth exchanges and common development

Accompanied by Chairman Zhou Wei, Japanese customers first learned in detail about Nano's advanced process breakthroughs and R&D achievements in recent years. Regarding the design structure of the product delivered this time, the technical teams of both parties conducted professional and in-depth discussions. Chairman Zhou Wei put forward targeted structural improvement plans on site based on the actual needs of customers, which fully demonstrated Nano's profound technical accumulation and customer-centered service concept in the field of mineral casting.

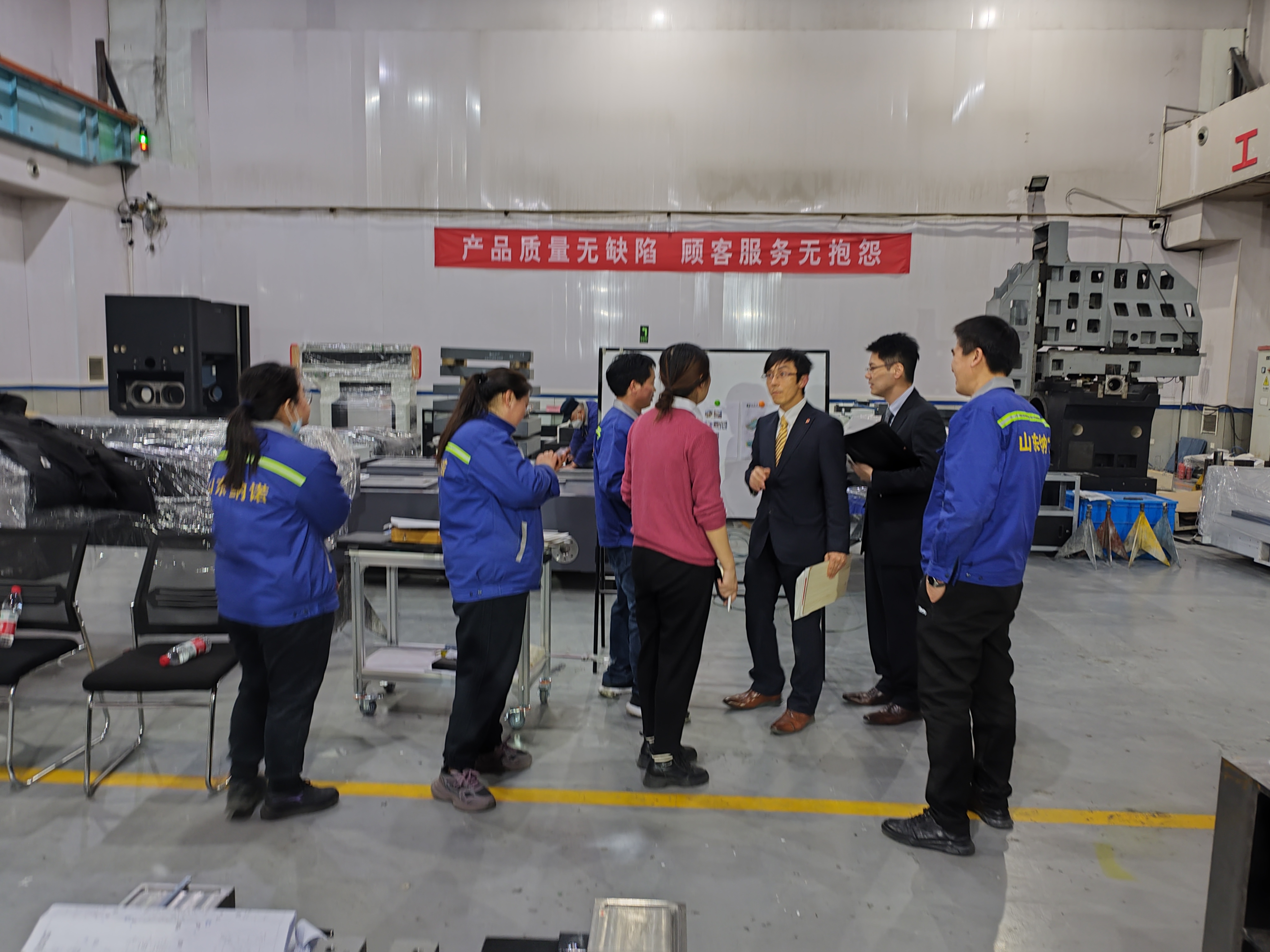

Subsequently, under the leadership of Chairman Zhou Wei, the customer delegation went to the Nano production base for an on-site inspection. In the machining production workshop, various large-scale precision equipment operate at high speed, and various complex parts are accurately processed amidst the roaring sound of machinery. The busy and orderly production scene leaves a deep impression on customers. Walking into the assembly workshop with constant temperature and humidity, the strict environmental control makes customers nod frequently. In the workshop, large mineral casting products of various shapes, mineral filled products and high-end hydrostatic guide rail products are neatly displayed, each of which demonstrates Nano's outstanding strength in the fields of materials science and precision manufacturing. Customers express their sincere appreciation for Nano's high standards in environmental control and product precision.

When the customer saw the actual mineral casting product he designed, he was so excited that he quickly stepped forward to take a closer look and couldn't wait to start the inspection process.

Nano's quality inspection team took out detailed inspection drawings and hundreds of pages of inspection reports, and began all-round strict acceptance:

Fine inspection of appearance: precise inspection of appearance, zero-defect texture

Precision dimensional inspection: all key dimensions accurately meet standards

Depth measurement of embedded parts: installation reference is accurate and reliable

Parallelism is strictly controlled: geometric accuracy meets the highest standards

Accurate weight verification: material density is uniform and stable

During the inspection process, the scene of four lifting rings steadily lifting a mineral casting bed weighing several tons became the focus of the audience. The customer looked in disbelief when he witnessed this scene. He was shocked by the excellent mechanical properties and quality assurance of Nano products and gave a thumbs up to the on-site staff.

After item-by-item verification, all on-site inspection data were completely consistent with the inspection report, and the zero-deviation results were highly praised and fully recognized by the customer.

This successful inspection by a well-known Japanese machine tool company is not only a strict inspection of the quality of Nano's products, but also a strong proof of Nano's manufacturing strength and its ability to connect with international standards. In the future, Nano will continue to uphold the craftsmanship of excellence, provide better mineral casting solutions to global customers with world-class quality standards, and work with partners to create a new chapter in intelligent manufacturing.

Contact us:

Tel: 0531-88917773

Website: www.jnnano.com

Email: eaststar@jnnano.com