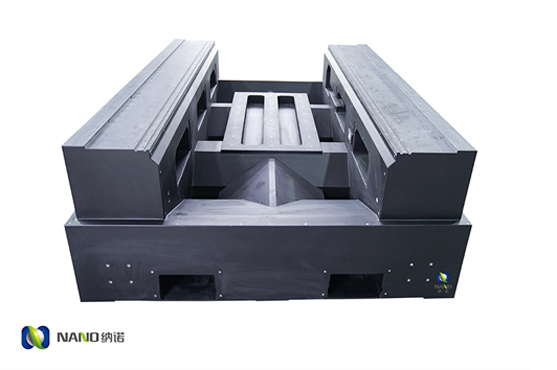

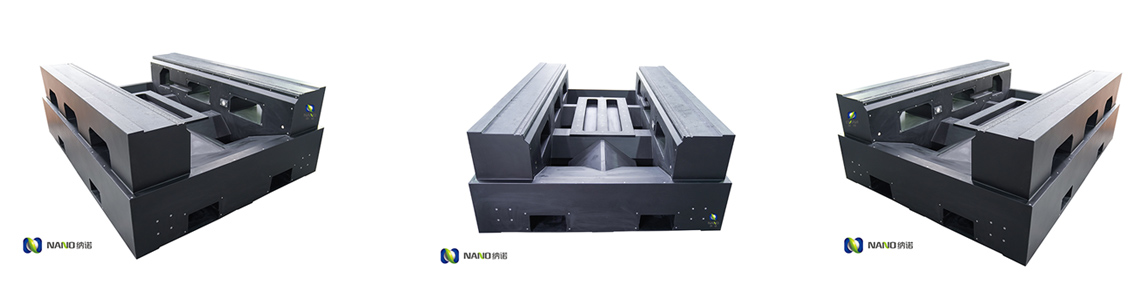

The epoch-making new material-mineral composite material for machinery/artificial granite/resin concrete. This material is a new type of material popular in the international machinery industry. It can replace the traditional cast iron and be used in machine tool bed, base, beam, column and other key parts. Mineral composite materials for machinery are patented products developed independently by Nano, which have complete intellectual property rights, and fill the gap of this project in China.

Virbration Damping

High precision

Flexible design

Cut costs

Heat resistance

Green

Threaded bolt and Insert

Threaded bolt and Insert Slotted and locating pinhole

Slotted and locating pinhole T-slot&Conduit piping

T-slot&Conduit piping Wire and through hole can all be integrated into the polymer base

Wire and through hole can all be integrated into the polymer base Can be integrated with natural granite,metal and ceramic to get the Datum surface that used for installing guideway

Can be integrated with natural granite,metal and ceramic to get the Datum surface that used for installing guideway